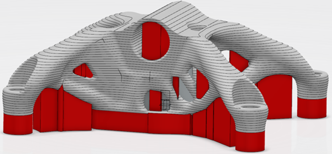

Optimize Design for Additive Manufacturing (DfAM)

Parts produced by Additive Manufacturing processes such as 3D Printing require designs that account for the layer-by-layer deposition of material. Additive Manufacturing offers the flexibility of placing material where its needed through the use of lattice structures and topology optimizations. Thermal distortions, residual stresses, proper support structure and interior lattice patterns are all important consideration when designing parts for 3D Printing. To optimize the designs of parts, we utilize advanced simulations technologies.

- Build planning and virtual printing

- Optimize tool path using Monte Carlo techniques

- Micro-structure evolution & grain growth

- Optimize process parameters to achieve “As-Designed” part from “As-Manufactured”

- Solutions for complex process controls addressing part overhangs, warping & residual stresses

- Determine support structure to minimize post processing and surface finish defects

Build plan for a metal 3D printed part